Each basic refrigeration system explanation:

1. Names the system.

2. Shows a schematic diagram of the system.

3. Describes how the system works.

4. Names some common uses.

5. Names the motrol controls used.

It is important that one become familiar with the fundamental operating principles of the common system described in this chapter.

The illustrations are not intended to show the expart parts and uses of actual units, instead, they explain the fundamental of construction and operation. Details and actual uses will be shown and described in lather chapters.

1. ICE REFRIGERATION

For years, ice (frozen water) was the only refrigerating means available. It is used in many refrigerating application. The usual ice refrigerator, Fig 1, is an insulated cabinet equipped with a tray or thank at the top for holding blocks or pieces of ice (see blue).

Shelves for food are located below the ice compartment. Cold air (see yellow) flows downward from the ice compartment and cool the food on the shelves below. The air become warmer and rises from the bottom of the cabinet(see red), up the sides and back the cabinet, flow over the ice, cools, and again flows down over the shelves.

Ice refrigeration has the advantage of maintaining the interior of the cabinet. at a fairly high humidity, food stored in this type refrigerator does not dry out rapidly.

Until the development of the mechanical refrigerator, natural ice refrigeration was quite widely used. Since then, artificial ice has been manufactured for refrigeration. Temperatures inside an ice refrigerator are controlled by the flow of air over the ice and trought the cabinet. Temperatures will usually range 40 and 50 F.

When it is necessary to use ice for cooling temperatures below 32 F. (0 C) ice and salt mixtures may be used. Temperatures down to 0 F, (-18 C) may be esay to get with ice and salt mixtures.

2. EVAPORATIVE REFRIGERATION

When a fluid evaporates heat is absorted. Evaporation of water is an example. This is why humans and animals perspire

Evaporation of moisture from the skin surface helps to keep one cool.

Another common of this principles is the “desert bag” used to keep drinking water cool This bag Fig. 2 made of a tightly woven fabric, is filled with drinking water. Since the bag is not waterproof, some water seeps through. Thus, the outside surface of the bag remains moist. Under desert conditions, which are usually both hot and dry, moisture on the surface of the bag evaporates rapidly.

A large parts of the heat necessary to cause this evaporation comes from the bag and the water in it. This heat removal cools the drinking water inside the canvas, keeping it a temperature several degrees below the temperature of the surrounding air.

3. EVAPORATIVE REFRIGERATION (SNOW-MAKING)

Another common aplication of water evaporation refrigeration is the method of making artificial snow for ski slopes. This device (snow machine) consists of water nozzle into which a high pressure jet of air is inserted. Water (see red) flow from the nozzle, as shown 3, and the air (see blue), under high pressure, causes the water to break up into tiny droplets (almost a fog). If the surrounding air temperatures is near freezing or below freezing, the droplets of water tend to evaporate and rapidly cool to the point where tiny drops of ice are formed. Using the method, artificial snow can be made when temperature of the surrounding air is 32 F, (0 C) or lower.

If the humidity is low, artificial snow can be made when the temperature is as high as 34 F. (1 C). This is possible because of the rapid evaporation and evaporative cooling caused by the humidity.

Evaporative condenser, often used in connection with air conditioners, are another example of evaporative cooling.

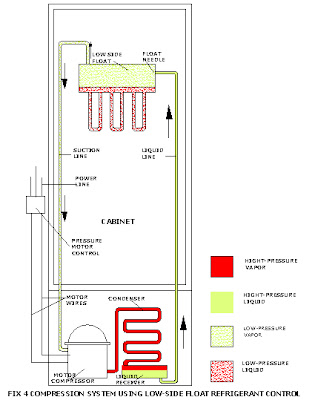

4. COMPRESSION SYSTEM USING LOW-SIDE FLOAT REFRIGERANT CONTROL

The "Low-side float" refrigerant control system was very popular in many of the early refrigerating mechanisms. It is also known flooded system.

This refrigerant, since it is a liquid on the low side, is at a low temperature. The cold liquid refrigerant will absorb considerable heat on both the on cycle and the off cycle.

Vaporized refrigerant moves through the suction (vapor) line to the compressor where it a compressed to a high pressure and discharged into the condenser. It it cooled gy the condenser, returns to a liquid and flows into the liquid receiver. The operation continues until the desired low temperature is reached.

The pressure on the low side in a flooded system such as the will vary with the temperature. the higher the temperature, the higher the low-side pressure.

The system shown in Fig 4. uses a pressure motor control. A spring-loaded pressure sensitive device on the suction line, or on the evaporator, actives a motor control switch. As the motor drives the compressor, the pressure and temperature in evaporator will be reduced. At a given pressure setting, the motor compressor will stop.

The cycle will be repeated as soon as the pressure in the evaporator rises to a level corresponding to the refrigerant temperature at which the motor compressor is to start again.

The cabinet temperature may be controlled by a temperature control switch. In case, the temperature sensitive element may be clamped to the fins on the evaporator.

The refrigerating cycle is often used on drinking fountains and other Installation, where a constant temperature is desired.

Since the pressures do not balance on the off cycle, it is necessary to use a motor which will start under a load.

Such a system requires a rather large refrigerant charge, as there is liquid refrigerant in both the liquid receiver and in the evaporator.

All flooded systems are quite efficient since cold liquid refrigerant wets the evaporator surfaces providing excellent heat transfer. These systems are easy to service.

The float needle and seat must be kept in good condition to avoid possible flooding of the low side.

Source :

Modern Refregeration and Air Conditioning By Andrew D. dan kawan-kawan